|

The Building of the Model of BCK 209 'Jeannie McIntosh'

Page 1 Page 2 Page 3 Page 4

Views of the sterns of BCK steam drifters - hoping to clarify for Ian whether they had a tug style stern.

|

|

The Building of the Model of BCK 209 'Jeannie McIntosh'

Page 1 Page 2 Page 3 Page 4

Views of the sterns of BCK steam drifters - hoping to clarify for Ian whether they had a tug style stern.

|

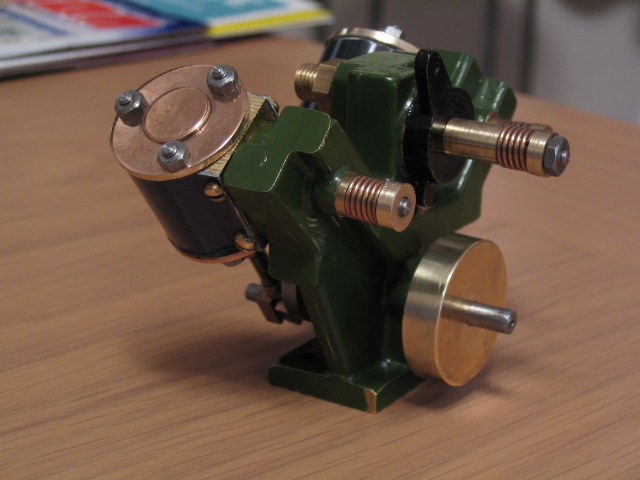

Engine components as supplied |

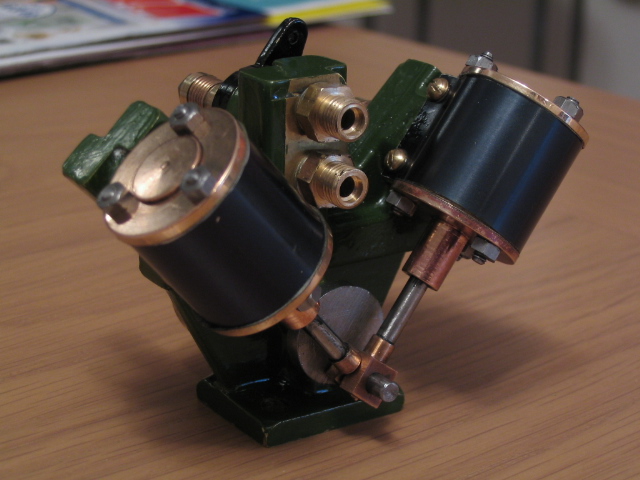

Some of the machined engine components |

The boiler shell |

The output end of the engine |

The battery is to give an impression of the size - not to drive it. |

The engine has had a short run on compressed air today, will now have to wait until the boiler is ready for a proper run! |

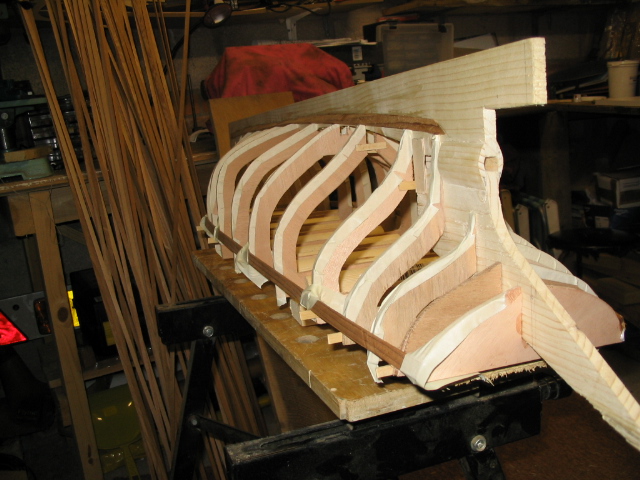

First planks on |

|

The keel is cut deeper than required to give stability during the build. When the hull is complete, I will reduce the depth below the planking by about half. |

|

Note the use of masking tape and ironing board |

|

|

|

|

|

|

|

|

|

'Ginnie' the overseer |

|

|

|

|

|

The filler is a standard car body filler, epoxy based, sands to a very smooth finish suitable for painting. Once the hull is ok, I will be coating it with probably 3 or 4 thin coats of twin pack epoxy to strengthen and waterproof it. Internally, it will get 2 coats of epoxy with a layer of v light glass cloth. This waterproofs and makes it v strong. The finished epoxy can be painted over with enamal or acrylic paint. I have also used car body paint with good results. Maybe a few words about materials is in order! The keel is made up from one peice of clear pine in this case. This particular boat is a bit different from others I have done in that the keel structure is partly external to the hull. Most modern ships, with the exception of sailing vessels, have a smooth bottom, often with bilge strakes on the turn of the bilge. The planking on the model is cedar. I got this wood from a wood reclamation yard, its previous life being tongue and groove cladding. I cut it into 3mm x 10mm wide planks using a small bench circular saw. |

Well, I removed the build shadows, wonder if I have enough room inside!

|

|

|

I will just have to add more planking now. Wont take long - these things happen! |