This page created September 2006.

This article was sent to me by an interested surfer.

|

J. Rendell Wilson

|

|

|

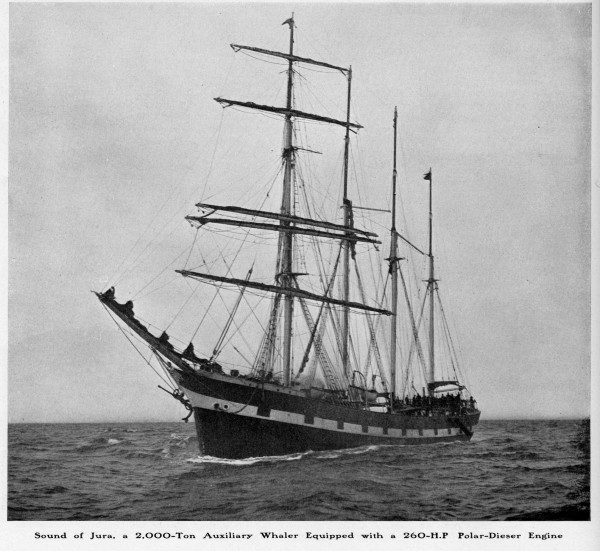

The success that has attended various Continental Diesel-engined ships has caused British shipowners to give, of late, really serious thought to the subject, and the launching of 'Toiler', by Messrs. Swan, Hunter & Wigham Richardson, of Newcastle-on-Tyne, has now been followed by the completion of a small fleet of power vessels of this class at the yard of Messrs. Smith's Dock Company, Middlesborough. The fleet, which is intended for the whaling industry in Antarctic waters, was constructed for the Southern Whaling & Sealing Company of North Shields, and comprises one 2,000-ton auxiliary and two fully-powered 92-foot whalers. The larger vessel, I understand, will be the parent ship to the smaller craft, returning at frequent intervals to port with the proceeds of the catches, and for food and fuel supplies, while the two whalers remain at work. Curiously enough all three vessels have been engined by the Aktiebolaget Diesels Motorer, of Stockholm, who were the constructors of the Polar-Diesel machinery of 'Toiler', the only other large English-built crude-oil engined ship of this class yet afloat. In a way, of course, it is a pity that the vessels are not entirely British or American; but no firm in these countries, it is to be regretted, could supply a marine Diesel engine of the required power and type for many months to come, although many are now actively engaged. However, the Polar-Diesel engines will no doubt give satisfaction, as they have already proved their worth in about a dozen big ships including the 'Fram', which is now engaged in the Amundsen South-Polar exploration expedition, that it will be rembered recently "stole a march" on Captain Scott's party. The 'Sound of Jura', the largest of the new fleet, is not, like the others, newly built, but was launched in 1906 (incorrect - should be 1896) Originally a sailing vessel she has, however, just been overhauled throughout, and has been installed with a 260-hp. Polar-Diesel engine as auxiliary power. She is 210 feet 3 inches in length, by 35 feet 6 inches breadth of beam, with 19 feet 5 inches draught, and is a four-masted barque built of steel. Her engine is of the two-stroke type, with four working, and two maneuvering cylinders, while the power is developed at 250 revolutions per minute. She already has passed her trials and has just left for Southern waters. The illustration shows her en route under power, making excellent headway in moderate weather, against a good wind. |

|

|

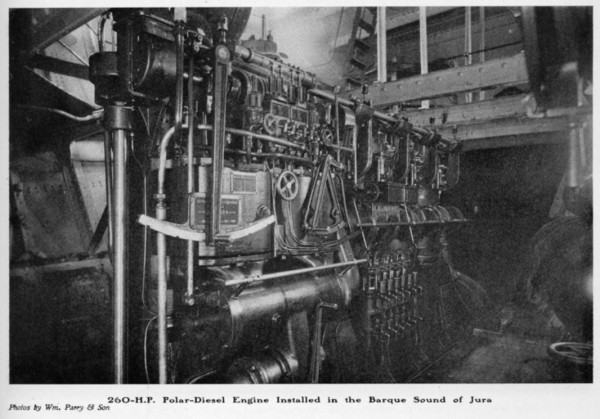

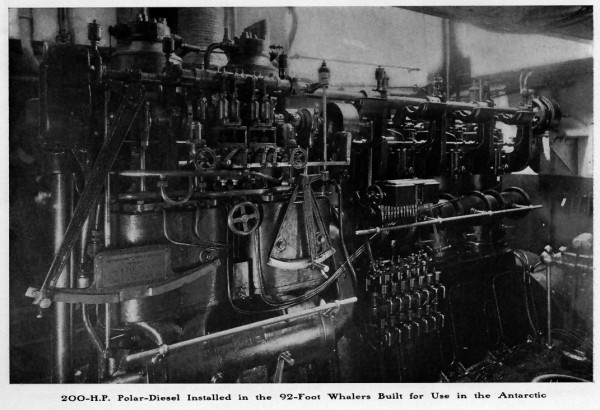

The two whalers are 92 feet long, by 18 feet breadth of beam and 6 feet 10 inches draught, classed by the British Corporation, and each is equipped with a four-cylinder (working) 200-hp. Polar-Diesel engine, running at 280 r.p.m. I have before me a copy of the test report on one of these engines made by Mr. G. Bremberg, surveyor to the British Corporation Registry, from which I give extracts. After several hours' continuous run, a fuel consumption test was made with the engine under full load for 30 minutes. At 282 r.p.m. the effective b.h.p. was 200 with a mean net load of 142 kgm., and the fuel consumption for the half-hour was 19,600 gr. The brakes used in the tests were supplied by Messrs. Heeman & Froude, Ltd., of Manchester. Another test was made, lasting ten minutes, to obtain the maximum effective power, and 222-hp. was obtained with the engine running at 292 r.p.m., on a net load of 152 kgm. Afterwards very satisfactory trials were made of starting, stopping and reversing. The exhaust gases were quite colorless, and the working of the engine was very regular, while there were no signs of overheated bearings. Regarding the 260-hp. engine installed in the 'Sound of Jura', of which an illustration is also given, a few more details will probably be of interest. As before mentioned there are four-working, and two maneuvering, cylinders: the two forward cylinders (left hand side of illus.) being the maneuvering, and are used for starting, stopping, reversing and air compressing. By this it will be seen that each working cylinder develops 65-hp. All cranks are set at 90 degrees so that there can be no dead centre. The maneuvering cylinder is double-acting and contains a compressor, which keeps a storage tank charged with air at a pressure of 150 lb per square inch; this air being used for starting the engine, and is admitted to the cylinders through valves in the maneuvering cylinder heads. By adopting this arrangement there is no necessity to temporarily shut off the fuel supply to the working cylinders, and they thus pick up the load very quickly. The second maneuvering cylinder is double-acting, and contains a two-stage air compressor. The compressors also supply air at 5lb per square inch for scavenging the working cylinders at the bottom of each stroke, the engine working, as before stated, on the two-stroke principle. In addition to cooling the the cylinder and piston-top the scavenging air leaves the combustion chamber clear of exhaust gases. |

|

|

The fuel injection valve is located on the cylinder head and is actuated by a rocker arm worked off an overhead cam-shaft, which is driven by a vertical shaft and gearing at the forward end off the crank-shaft. Each of the fuel valves is supplied by its own pump, and is adjustable. When the exhaust is dirty, which can be discovered by opening a cock on the exhaust branch, the fuel supply is reduced until the right amount is being consumed. Reversing is practically instantaneous and is carried out by shifting the cams that control the air injection valves, at the same time automatically shutting off the fuel supply for a moment. The maneuvering cylinders then come into action and are used until the working cylinders take up the load in the reverse direction. So it will be seen that backfiring is almost an impossibility. An important feature with engines of the Diesel variety is the low lubricating-oil consumption, as any excess is apt to burn and clog the piston rings, while it will also clog the compressor valves. With this engine, all that is necessary is one drop of oil about every ten minutes to each bearing, etc. The sight-feed lubricators provided, can be seen grouped on the crank-case in the center of the engine, with a small feed tank above. The group on the upper part of the maneuvering cylinders are the four fuel pumps, and the small feed pipes can be traced to each cylinder. Above the unions can be seen the small feed adjusting screw referred to previously. Fuel consumption is very economical, being about .45 lb to .5 lb per horsepower per hour, which is almost as low as yet obtained by any four-stroke type Diesel engine. Messrs. Swan, Hunter & Wigham Richardson are now constructing a 400-hp. marine engine on this design. While engaged on this article, readers may be interested to learn that I have just received a letter from the famous German engineering firm of Fried Krupp of Kiel-Gaarden, stating that in addition to other large marine oil engines under construction, they have four six-cylinder engines, each developing 1,150-hp. at 140 r.p.m. and two six-cylinder engines of 1,750-hp. each at 125 r.p.m. These six big engines, aggregating 8,100-hp. will be fitted in three vessels owned by the Deutch-Amerikanische Petroleumgesellschaft. In addition they are building eight 850-hp. engines, and two of 600-hp. apiece, as well as a large number under 500-hp. |